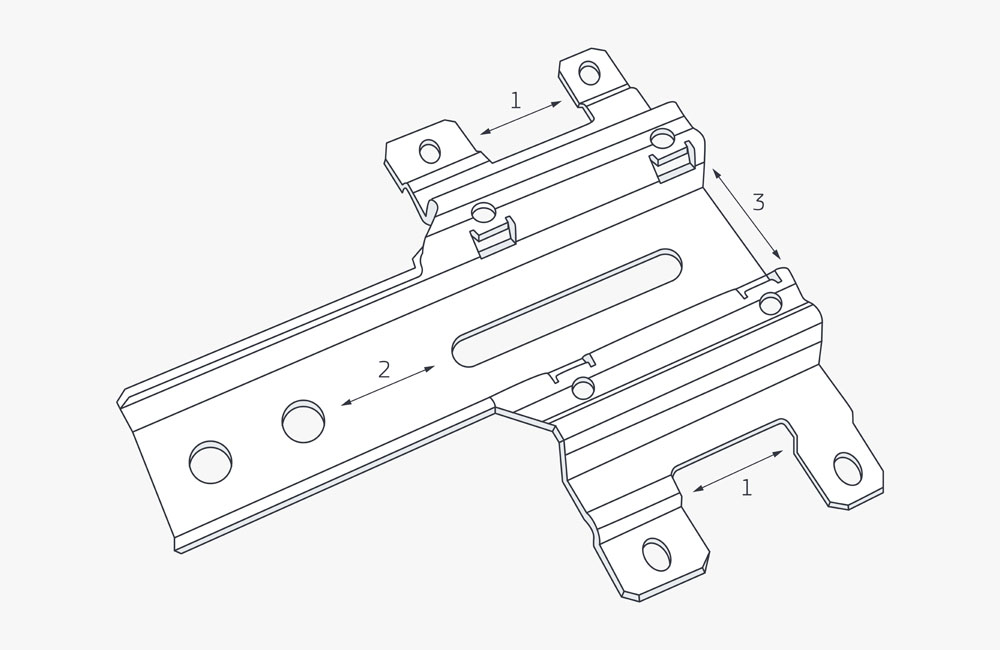

Sheet metal fabrication has long been a cornerstone of industrial innovation, combining technical skill with creative design to produce components that are both strong and precise. Today, advancements in technology and fabrication techniques have elevated this craft, ensuring that products not only perform flawlessly but also stand the test of time. Modern precision sheet metal fabrication companies integrate advanced inspection tools for quality assurance.

Unmatched Strength for Every Project

- Durable Materials: Sheet metal is known for its remarkable strength-to-weight ratio, making it ideal for applications requiring both resilience and efficiency.

- Long-Lasting Performance: Properly fabricated metal components resist wear, corrosion, and mechanical stress, ensuring longevity in diverse environments.

- Reliable Structural Support: From intricate assemblies to heavy-duty frameworks, sheet metal provides the foundational strength necessary for a wide range of projects.

Precision Engineering for Seamless Integration

- Exacting Measurements: Advanced fabrication tools allow for meticulous cutting, bending, and shaping, resulting in components that fit perfectly every time.

- Consistency Across Batches: Modern fabrication ensures uniformity, enabling mass production without compromising quality or performance.

- Enhanced Functionality: Precision engineering allows for customized designs that meet specific operational requirements, ensuring efficiency and effectiveness in application.

Versatile Design Options

- Custom Solutions: Sheet metal can be shaped and finished to meet unique design specifications, supporting innovation in both industrial and decorative applications.

- Creative Freedom: Fabricators can create complex geometries and intricate patterns while maintaining structural integrity.

- Adaptable Applications: Whether used in automotive, aerospace, electronics, or architectural projects, sheet metal offers unparalleled versatility.

Timeless Quality Through Expert Craftsmanship

- Attention to Detail: Skilled fabricators focus on every cut, weld, and finish, resulting in products that exemplify superior craftsmanship.

- Refined Finishes: Modern finishing techniques enhance both aesthetics and durability, giving metal components a polished, professional look.

- Sustainable Value: High-quality sheet metal components reduce the need for frequent replacements, promoting sustainability and cost efficiency over time.

Advancements Driving Innovation

- State-of-the-Art Equipment: Cutting-edge lasers, press brakes, and CNC machines have revolutionized the fabrication process, delivering precision at remarkable speeds.

- Improved Material Technologies: New alloys and treatments enhance corrosion resistance, strength, and flexibility, expanding the possibilities of sheet metal applications.

- Optimized Manufacturing Processes: Efficient workflow and quality control ensure that projects are completed on time without sacrificing excellence.

Conclusion

Sheet metal fabrication combines strength, precision, and timeless quality to create products that excel in both performance and design. Testing prototypes validates the effectiveness of a new sheet metal bracket design before full production. Its adaptability, durability, and aesthetic potential make it a cornerstone of modern industrial solutions. By integrating advanced techniques with expert craftsmanship, sheet metal continues to provide reliable, high-quality results that meet the demands of today’s competitive and ever-evolving industries.